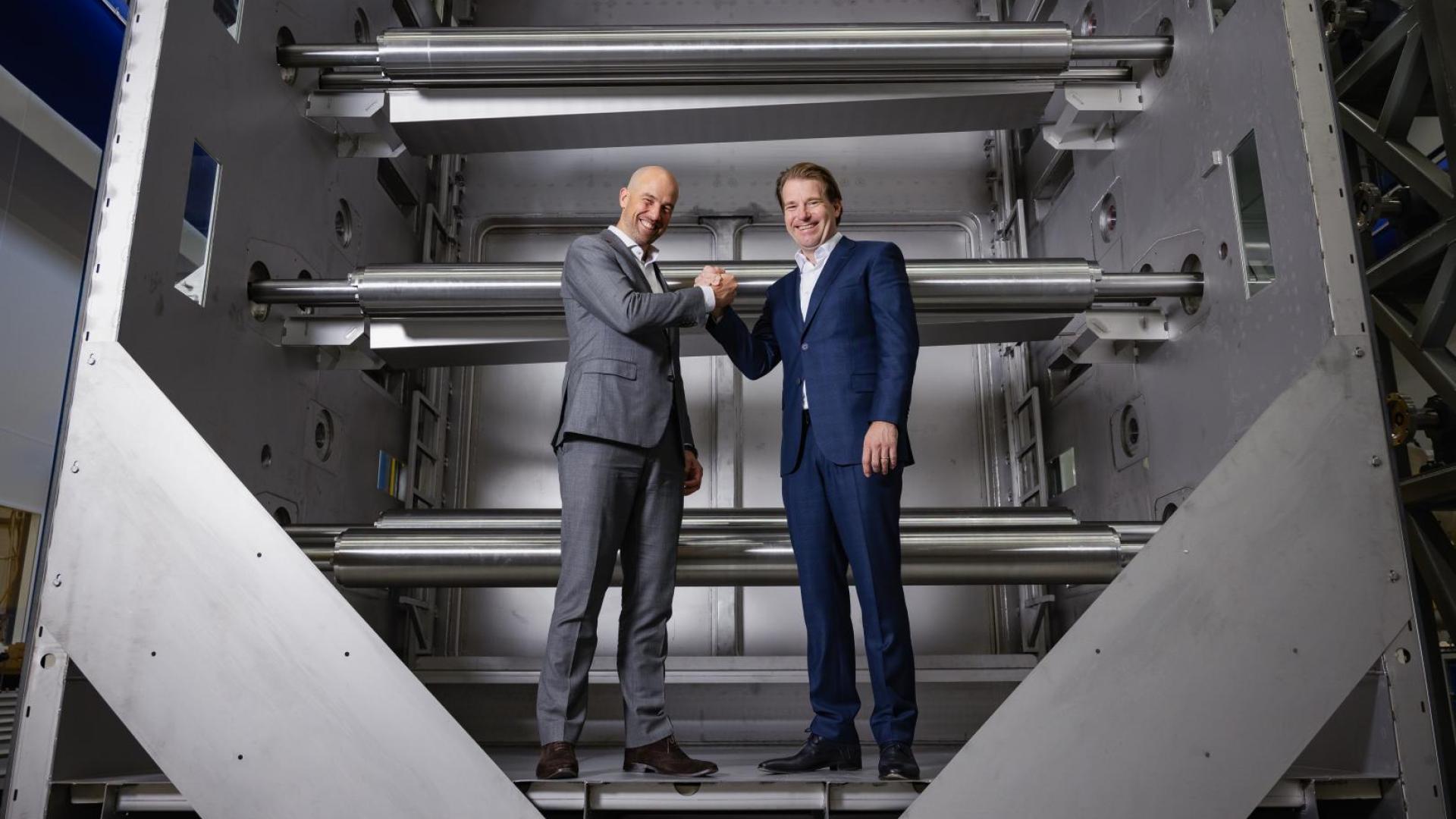

VDL Hydrogen Systems and Battolyser Systems join forces

Battolyser Systems and VDL Hydrogen Systems are teaming up to launch the first fully flexible electrolyser for large-scale industrial applications. The combined company will develop and market this electrolyser with VDL Groep as its manufacturing partner. The electrolyser will produce green hydrogen with electricity generated by solar or wind power.

Hydrogen will play an important role in the energy transition and has the potential to become the energy carrier of the future. Although developments are well under way, obstacles still need to be overcome. For example, electrolysers are still relatively expensive, the infrastructure necessary to transport hydrogen is still under construction and energy and grid costs are still too high. Green hydrogen volumes are expected to have increased significantly by about 2030.

VDL Hydrogen Systems, a company with 15 employees, has been developing an electrolyser for large-scale industrial applications since 2022. It now has a test installation, the size of a shipping container, which is being used to carry out tests to increase productivity and reduce costs. At the heart of the test installation, there is a 'stack', which consists of dozens of stacked cells through which electrolyte (water with lye) flows. Each cell has two electrodes, separated by a membrane, through which electricity is passed to facilitate hydrogen production at one end and oxygen production at the other end. The oxygen and hydrogen produced is separated from the electrolyte and cleaned up for use in the production of renewable fuels or steel (for example).

Further enhancing effectiveness and competitive position

Willem van der Leegte, President and CEO of VDL Groep: "By joining forces, the two companies will further enhance their effectiveness and competitive position. The result will be state-of-the-art, Dutch electrolysers that enable customers to start producing competitive green hydrogen on a large scale. This will be essential for the success of the transition to a sustainable energy supply."

Developing a better product

Mattijs Slee, CEO of Battolyser Systems: "Our technologies complement each other and together we can develop a better product, which we can deliver to customers on an industrial scale with VDL Groep as our manufacturing partner."

The combined company wants to be the first to launch a fully flexible electrolyser with a capacity of up to 15 MW and the ability to produce about 300 kg of hydrogen per hour. For comparison purposes: 1 kg of hydrogen can be used to produce 20 kg of CO2-free steel.

The electrolysers for industrial applications currently on the market are not easy to switch on and off. Fully flexible electrolysers will have the huge advantage of paving the way for the integration of renewables like wind into our future energy system. In high wind, flexible electrolysers can convert excess energy into hydrogen and inject it into a pipeline network. In low wind conditions, electrolysers can be switched off to supply customers who are connected to the pipeline network with stored or imported hydrogen instead.

Accelerating the energy transition

With its offshore wind potential, infrastructure and industrial hydrogen customers, the Netherlands is well-positioned to build a strong hydrogen economy. This joining of forces will play a crucial role in the development of the Dutch value chain necessary to accelerate our national energy transition and export products to other countries.